Catheter Tipping Machines

Multi-functioning catheter tipping machines that do it all – forming, tipping, bonding and flaring – prove to be a great asset to a medical manufacturer's production environment.

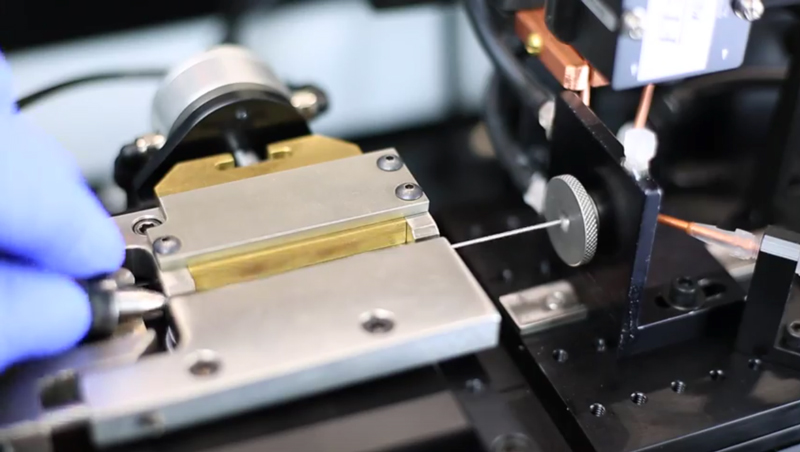

RF tipping machines are versatile, capable and most importantly, accurate. They are used to achieve precise, quality parts in a consistent manner. Whether balloon bonding or flaring braided material, radio frequency can assure the quality medical producers demand.

The particular settings used to produce any given device are called recipes. Recipes are stored in the machine so quick and easy setup can be achieved when multiple catheter parts are formed on one machine. When a machine is dedicated to only one type of catheter, the power and consistency of the equipment will ensure maximum output time for high capacity production.

Custom tooling.

A machine that allows for custom tooling and tooling changes is a valuable long-term asset. Clamps, coils, dies are some of the components designed and crafted for each catheter application to ensure consistent, quality product output. A medical device manufacturer needs to maximize their employees' time.

Catheter Hole Drilling Machines

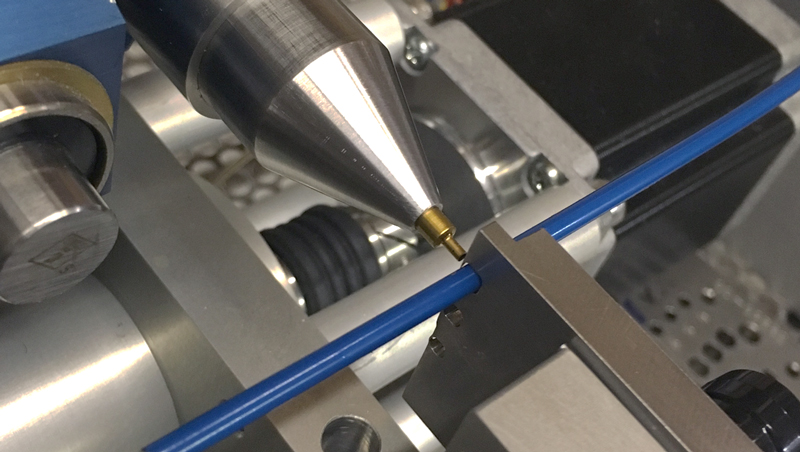

Accurate, cost-effective automated technology in side hole catheter drilling is a catheter manufacturer's dream. When added to that is the capability to extract the hole core at the moment of drilling, excitement is in the air.

Demand for precision hole drilling is growing tremendously as medical professionals demand greater and greater sophistication in their healthcare devices. It's a win for patients when medical manufacturers can produce to the exacting technical specifications hospitals require. Hole diameter and placement are critical features of the device's performance.

From large single side holes, to dozens of minute holes in rows or other patterns, it's critical to utilize a precision machine in the catheter manufacturing process so consistency and quality reign. To capture and isolate the cores into a vacuum chamber while drilling exponentially assists in achieving a superior medical manufacturing environment, as loose cores can become a hazard.

Drills must be sharp and accurate so that machines punch burr-free holes. Long-lasting drills are also critical to keep downtime to a minimum in the highly competitive catheter industry.

Accuracy. Consistency. Quality. All are essential components of a catheter drilling machine.

View Catheter Machines...

View catheter tipping machines in operation and take a video tour of equipment capabilities. Having the right – and best – machines will add tremendously to the bottom line.